Alucha Extracts Lime from Paper Waste for Use in Paint, Glue, and Plastic

07-10-2025

Paper waste is full of calcium carbonate, a type of lime, which can still be effectively used in paint, paper, glue, rubber, or plastic. The Dutch scale-up Alucha extracts this substance from paper sludge to help large companies like Essity, AkzoNobel, Dyka, and Bostik reduce their CO2 emissions and become more circular. The construction of a new demo plant can quickly commence once the company secures its funding completely.

How simple can some circular solutions be? You extract a filler from the waste of paper factories and sell it to paint and glue manufacturers, helping them achieve their climate and circular goals. That is the idea behind Alucha.

How simple can some circular solutions be? You extract a filler from the waste of paper factories and sell it to paint and glue manufacturers, helping them achieve their climate and circular goals. That is the idea behind Alucha.Perhaps it would have been easier with another name

CEO Gijs Jansen started the company in 2004 in Barcelona while he was pursuing his MBA. 'We started recycling beverage cartons in Spain, extracting aluminum from them. That’s where the name Alucha comes from. 'Alu' stands for aluminum, and 'lucha' means struggle in Spanish. We thought it would be a struggle to make this happen. In hindsight, we should have named the company Alu-easy. Maybe that would have made it all a bit easier,' he says.

Alucha built a demo factory for the recycling of beverage cartons, executed a nice project, but ultimately the market was too small to establish a company around it. Meanwhile, Jansen observed trucks leaving the paper factory loaded with waste sludge. This sparked the idea to develop a solution for that. After moving back to the Netherlands with his family, Alucha made a kind of restart.

My calcium carbonate now also in Brabant

The paper industry uses almost 90 percent recycled paper to create new paper and cardboard. However, this old paper contains fillers such as calcium carbonate, which is used to make the paper white or glossy. Many of these substances end up as waste in paper sludge, with 9 million tons being burned or landfilled annually in Europe. This results in significant CO2 emissions since a lot of greenhouse gases are stored in calcium carbonate.

At the same time, new calcium carbonate is extracted worldwide from limestone and chalk mines, for example, in the Alps in Europe. One such mine is now also located at Alucha in the Brabant municipality of Cuijk, near Nijmegen. However, calcium carbonate there is not mined from limestone rocks but separated and reused from paper sludge using pyrolysis technology.

Oil and calcium carbonate from paper sludge

Alucha converts paper sludge into two products: calcium carbonate and bio-oil. Through pyrolysis (heating without oxygen), the paper fibers are transformed into a hot gas, separating them from the filler, calcium carbonate.

The gas is cooled into a type of liquid wood, a biofuel that paper mills can reuse in their processes. 'Those factories require a lot of heat, and by using this oil, they can save natural gas,' Jansen explains. 'In the long term, we also want to produce biobased chemicals from this, but that is still in the R&D phase.'

This oil is currently just a by-product. The focus is on the filler, which constitutes the majority of the paper sludge. Alucha calls this Circular Calcium Carbonate, or CCC for short. ‘We can reclaim this. This is the circular variant. The virgin variant is extracted in the mountains. In Europe alone, more than 50 million tons of this material is mined annually. The paper industry is a major consumer. It is also used in paint, plastic, carpets, rubber, glue, sealants, PVC, and more. It is the most used filler available, and we are replacing the virgin variant. That is our market,’ says Jansen.

Paint and glue not yet circular

Alucha has large companies as clients both at the front and back end. The sludge comes from big paper factories that want to dispose of their waste sustainably. They sell the circular material to big paint and glue manufacturers. 'This is a unique product made from post-consumer waste that currently doesn't really exist,' says Jansen.

'The paper industry is already a leader in circularity through its use of recycled paper, but the paint or glue industry is not. If you walk into Gamma now, you won’t find a can of paint with circular content. Our CCC is a very cost-effective way to increase circular content. A jar of paint can contain 30 to 40 percent of that filler. That’s why we are closely looking at industries that have difficulty obtaining circular raw materials, such as the glue, rubber, and paint industries.'

Mobile pilot plant for testing

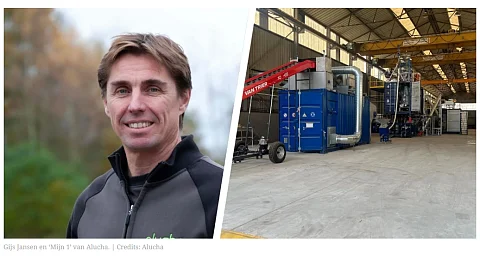

The concept is simple, but it requires high-end technology. Alucha developed this together with TNO and later with the University of Twente. Together, they built a mobile pilot plant in Twente, which is now located in Cuijk. 'We use it to create products for customers like AkzoNobel or plastic producers. They all need to conduct tests with our materials. Initially, they require a kilo, but eventually, they may need 200 kilos or a few tons, which we can produce in that pilot plant,' Jansen explains. They refer to this installation at Alucha as 'Mine 1.'

Projects with large companies

Since 2016, Alucha has been collaborating with the paper factory Essity in Cuijk, which produces tissue products like toilet paper, kitchen towels, and napkins. They generate a lot of paper sludge as waste annually. Since last year, both companies have been part of the Re&Uce project. This project aims to reduce the CO2 emissions of paper factories with a LIFE subsidy from the EU. By extracting calcium carbonate from the paper sludge and converting the organic materials into biofuel for Essity's factory, Alucha can help that company save 19.7 kilotons of waste and 4,300 tons of CO2 emissions each year.

The subsidized project for the European innovation program OPZuid also aims to reduce waste from the paper industry, as well as the CO2 emissions released from burning or landfilling it (methane).

Another goal is to increase the recycled material content in glue and plastic. Besides Essity and Alucha, glue manufacturer Bostik and plastic pipe producer Dyka are also part of this project. The aim is for Dyka to use 10 percent more recycled material in its pipes and for Bostik to use 20 to 60 percent in its glue.

Demo factory for ‘Mine 2’

Alucha currently has a team of ten permanent staff and is located next to the paper factory Essity in Cuijk, where they plan to build a larger factory as part of the LIFE project: 'Mine 2.' 'This will be the first line at a commercial scale. If it performs well, we will add more lines,' says Jansen. 'Everything is ready to start building. We have all the permits we need. We even have electricity—a miracle in the Netherlands.'

With 'Mine 2', Alucha also aims to serve the partners from 'Mine 1' and the OPZuid project. Once the factory is fully operational, it could save them between 1.2 and 5.5 kilotons of CO2 emissions annually.

The final hurdle to construction is funding, which is not fully secured yet. There have been attractive subsidies from Europe (EU Life) and the Netherlands (RVO DEI), and there is interest from investors,' says Jansen. 'We are close, but not there yet.'

The question is also whether Alucha's CCC can eventually compete on price with new calcium carbonate from the Alps. Or if the bio-oil will be cheaper than natural gas? According to Jansen, this varies by market segment. ‘For some industries that use high-quality fillers, we are price competitive; in the rubber market, we can even be cheaper. We will focus on these markets. For other markets, we may be slightly more expensive,’ he explains.

GCA program helps startups scale up

This year, Alucha was one of the participants in the Green Chemistry Accelerator (GCA). This program was established along with Invest-NL and the Regional Development Agencies (ROMs) to help startups scale up to a fully-fledged company. They receive assistance in finding customers, and during scaling tables, investors discuss next steps for financing.

Jansen: ‘You learn a lot from the other companies and how they tackle their problems. We also took good advantage of external experts. You always receive feedback, and your plans can always be better. You have to seize all the help you can get. Then you have a good chance of success.’

This article previously appeared with our media partner Change Inc., author André Oerlemans.